Introduction to Constructed Wetlands

Our team is committed to spreading constructed wetland ecotechnology into the regions most in need: countries with little sanitation infrastructure, semi-desert/desert and tropical climates, coastal areas and places where water conservation and reutilization is essential.

But we also work around the world since constructed wetlands are a green solution, using little to no machinery, and adding diversity and beauty in the place of conventional sewage treatment. The world is facing increasing scarcity of potable freshwater, so greening re-using and recycling so-called “wastewater” is an important method of protecting against sewage contamination of water sources. Constructed wetlands for sewage treatment also protect the environment and human health, in addition to reducing water consumption.

There has been increasing interest in using constructed wetlands as interface ecosystems for wastewater treatment since early studies demonstrated their effectiveness at removal of nutrients and suspended solids. Constructed wetlands using surface-flow or subsurface flow emergent vegetation or aquatic plant systems have gained increasing acceptance and are spreading around the world.

Since such natural or constructed wetlands are often limited by solar insolation and show increased rates of uptake in warmer climates, such systems may be expected to operate even more efficiently in milder Mediterranean, subtropical and tropical regions than in the continental US and northern European conditions where they were first developed and where they are however still in great use, although much greater surface in necessary to achieve same levels of treatment. Constructed wetlands can also be made increasingly responsive to on-site sanitation situations (as opposed to centralized sewered sanitation), where lack of localized treatment presents great public health risks, as in much of the poorer parts of the world.

But the potential advantages in using constructed wetlands extend far beyond their efficacy for improving human health by preventing disease transmission through contact or through pollution of sources of potable water. Constructed wetlands offer more than simply an alternative and low-cost, low-maintenance form of wastewater “treatment”. In an expanded paradigm, more suited for the current global situation, constructed wetlands are increasinglty appreciated for their potential role in water conservation, through greening, creating diverse landscapes and irrigating potentially harvestable plants through the re-use of the wastewater, thus saving higher quality or potable water which might otherwise have been applied.

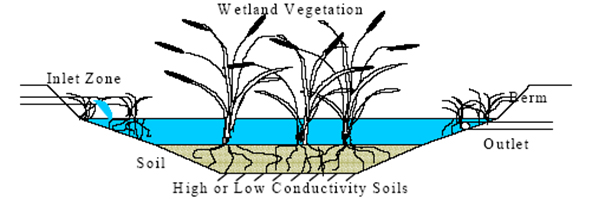

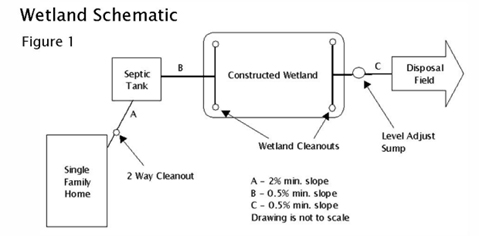

There are several types of constructed wetlands for sewage treatment. Schematic of an open-water or free-water surface constructed wetland for wastewater treatment.

Surface flow constructed wetland

Most of the biological activity in a surface flow constructed wetland occurs in the top layer of the soil, the stems of the plants and in the water itself. Frequently there is no liner under this type of constructed wetland and there may be water which percolates into the soil or groundwater, depending on the permeability of the soils.

Early constructed wetlands of this type included ones which used floating plants like Eichornia, water hyacinth, and emergent plants

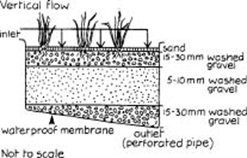

Right: Vertical flow system showing that incoming wastewater is pumped to a network of pipes on the surface, and then the wastewater flows down (vertical direction), thus increasing aeration and treatment levels especially of nitrogen and BOD.

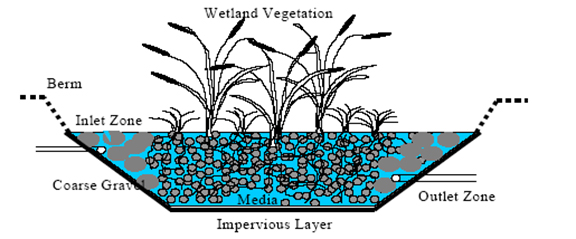

Schematic of a horizontal flow Wastewater Garden (constructed wetland)

Typically these systems have a water-tight liner of compacted clay, concrete or geomembrane materials such as polyethylene or EPDM pond liner.

Higher in initial cost of construction, these subsurface flow wetlands can often be sized five times smaller than open-surface constructed wetlands because of their longer hydraulic retention time and intensity of treatment.

We typically use horizontal flow subsurface flow wetlands, sometimes incorporating a vertical flow wetland for larger projects or when nitrogen removal needs to be increased.. They require far less area than surface flow wetland need. They also produce no malodor, prevent mosquito breeding and eliminate the chances for accidental human contact, because the wastewater is kept at least 2 inches (5 cm) beneath a dry layer of gravel.

They are also very passive systems, not requiring pumps or electricity, and as such have advantages in terms of cost, maintenance requirements and the need for purchased equipment and replacement parts. These characteristics also make them more suitable for onsite treatment close to houses or businesses.

In such installations, continuing to make the constructed wetlands biodiverse, attractive gardens, led to use of the term “Wastewater Gardens” to differentiate this approach from the monocultural systems, often called reed beds, which use only one or two species, most commonly Phragmites australis, and/or Typha latifolia.

Typical schematic of layout for individual residence constructed wetland, using septic tank for initial treatment, followed by constructed wetland and either creating a green landscaped zone or using the treated water for growing appropriate crops. For larger applications, many individual septic tanks can be connected to the same constructed wetland.

Constructed wetlands can also be applied to larger populations, such as office clusters, communities of homes or village/town scale projects. There are numerous examples in the United States for example of subsurface flow wetlands treating wastewater of populations of up to 20,000 people, involving millions of liters or gallons of wastewater daily (in France the city of Honfleur treats all its wastewater through constructed wetlands). In these cases, the wetlands can be scaled in size for a single-treatment area, or through a series of decentralized, regional systems, close to the points of origin of the wastewater, to minimize the cost and extent of pumping and piping and to take maximal advantage of gravity flow.